About Us :

We are a traditional organization following the age-old tradition of manufacturing Wooden Safety Matches started by our ancestors from 1933. We are known for our commitment and adaptation to modern technologies. With our meticulous efforts we have established ourselves as one of the proficient Manufacturers and Suppliers of Superior Light Veneer Matches, Premium Cardboard Matches and Eco Cardboard Matches. We cater to the domestic and Exports market. Currently, we have been supplying our products under the brand names Superior Lamp, Superior Light, Peacock, Victoria Major, Avro and Gudiya. Our quality maintenance and customization of matches according to clients’ requirements makes us their foremost choice.

Vision :

Bringing energy to homes and a livelihood for over 500 families.

Mission :

Aiming to bring energy to every home by manufacturing traditional safety matches with modern technology.

Company History

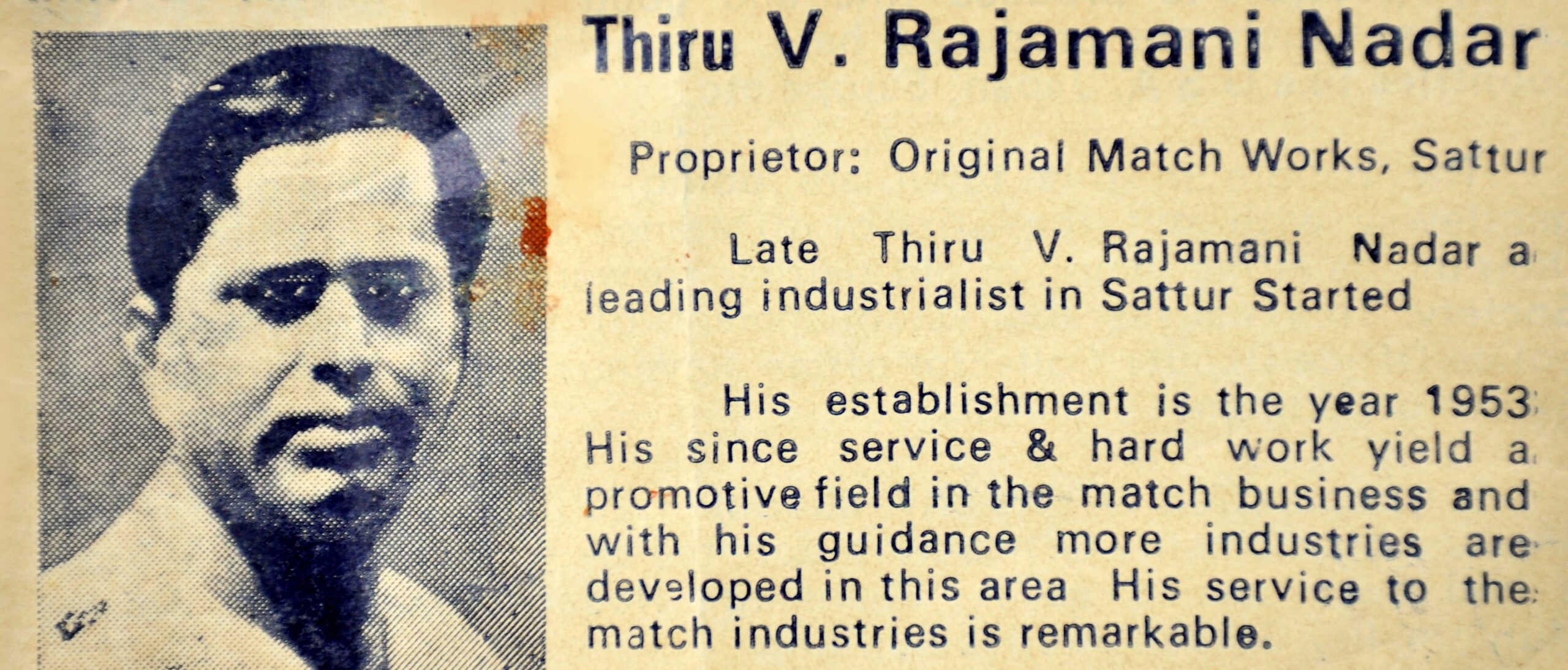

FOUNDER (first generation):

Mr. V. Rajamoney Nadar founded M/s Sattur Original Match Company on December 16th 1933 at a small town in south India called SATTUR. He completed a B.A. degree in English Literature and worked at the West Indian Match Company in Kolkata for some time and then returned to Sattur. He started the first handmade match manufacturing unit in Sattur. He later traveled to Kerala and started splints and veneers manufacturing units in Olovakkot and Pambady in the year 1942. He started to market his matches under the trade mark “SUPERIOR LIGHT”. He started to market throughout India. It was first supplied in the town of CHURU in RAJASTHAN and is continued to market there since then which means 68 years. He was obsessed to always make good quality matches and creating markets with a long-term vision. He passed away due to sudden heart failure on May 2nd 1955 at the age of 50 leaving behind his wife and eight children.

As written in “THE HINDU” on May 25th 1955:

Shri V. Rajamoney Nadar, a Successful business man, a man of profound industrial knowledge and pioneer in match industry in south India, interested himself in educational and public activities from his earlier life. The credit of manufacturing matches in the south especially in Sattur goes to him. His multifarious activities in promoting the cottage industry and his charitable disposition have won for him name and fame besides innumerable friends and admirers. As the secretary of the South India Swedish Match Manufactures Association, he had sponsored in solving several problems of the match industry. His establishment has given employment to more than 600 persons.

Shri V.R. Palanisamy (SECOND GENERATION)

His reign was carried on by his eldest son, Mr. R. Palanisamy, who at the time of his father’s death was just 17 years of age, had taken over helm. He was a man of great perseverance and soft nature with profound knowledge of the match industry. He served many terms as the member of the Regional Advisory Committee of the Central Excise and created awareness among the match industry as many at that time had very less knowledge about the working of the Central Excise. He passed away on July 28th 2002 due to sudden heart failure.

Mr. P. Sajeev (THIRD GENERATION):

After the year 2000 the industry saw a transformation from a full handmade labor-intensive industry to mechanization. In the year 2007 we installed our semi –mechanized dipping machine. As we specialize in manufacturing the traditional veneer (wooden) matches we also introduced machinery the label pasting, side painting, unit packing, and shrink packing machine to a nearly completely mechanization in the veneer manufacturing sector. We are the only mechanized unit in Sattur and one among the two in the full Industry. The specialty in the veneer matches is that, it does not absorb moisture and is very suitable in rainy places and popular in the rural areas. Manufacturing veneer matches is very labor intensive and time consuming.

Why Us?

- Traditional Background: We are a third-generation company, in existence since 1933.

- Product knowledge: Transformed from traditional hand- made manufacturing methods to modern manufacturing methods.

- Required Infrastructure: Manufacturing safety matches using semi-automatic machinery to meet required quality standards.